Basics of light curing adhesives

UV curing adhesives, or light curing adhesives, cure quickly when exposed to light. We will discuss advantages and disadvantages.

UV curing adhesives, or light curing adhesives, cure quickly when exposed to light. We will discuss advantages and disadvantages.

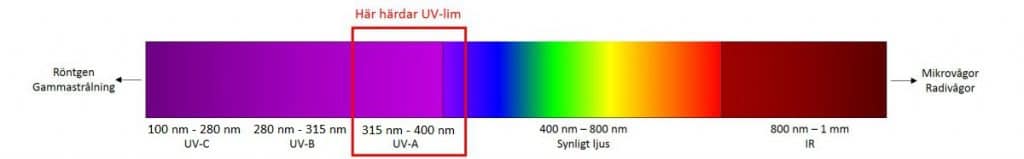

UV curing adhesives, often called light curing adhesives, are adhesives that cure when illuminated with light. But not just any light – different adhesives are adapted to cure at different wavelengths. Usually it is within the spectrum of UV-A or ‘blue light’, i.e. approximately 365 nm to 405 nm, which is why the term UV curing adhesive has been developed.

A light curing adhesive is not really a type of adhesive, but a curing mechanism. There are for example light curing acrylics, epoxies, silicones and cyanoacrylates.

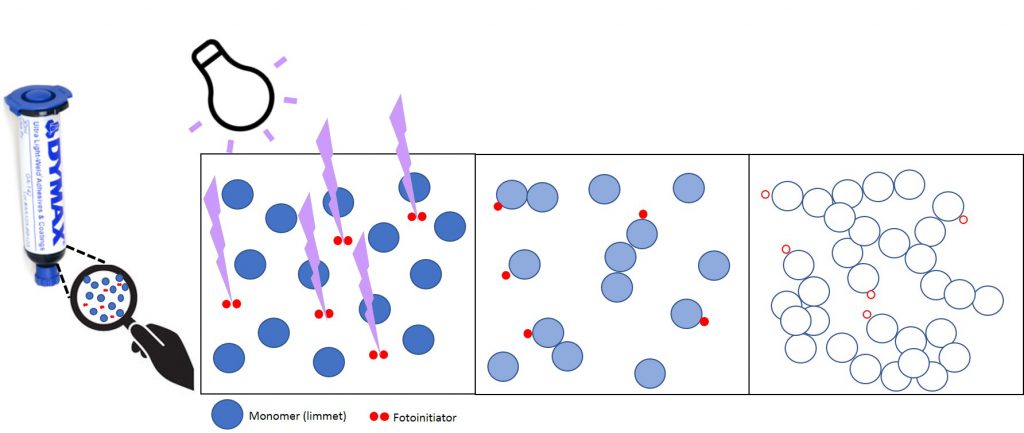

There are, as mentioned, several different types of light curing adhesives and they are based on different chemistries. What they have in common is that the adhesive formulations contain monomers and oligomers (building blocks for the adhesive) and some type of photoinitiator (small molecule that initiates the curing reaction with the help of light).

When the photoinitiator absorbs light of a certain wavelength and intensity, it starts a polymerization reaction – the adhesive cures. It is important to make sure that the adhesive matches the UV lamp meant to be used: Intensity, wavelength of light, LED or broad spectrum, and the configuration of the lamp are all important aspects to consider.

The light from a lamp must have an intensity over 50 mW/cm2. Sun light, which has an intensity around 2-5 mW/cm2 will thereby not suffice.

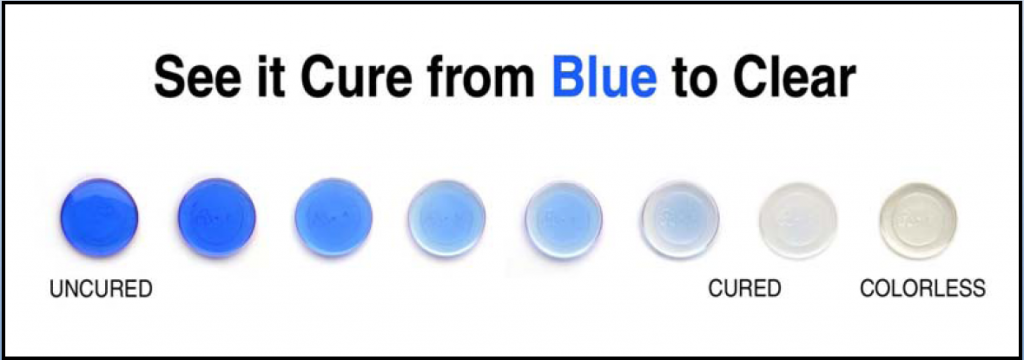

So long as the adhesive bond is illuminated by the light, the reaction carries on. However, if the light is removed too early, the reaction pauses. Consequently, it is important to cure a light curing adhesive the correct amount of time. Too short curing time leads to incomplete cure (which is why a safety factor is incorporated) and too long cure time can cause degradation of the adhesive. Degradation will weaken the bond and cause discoloration. Exposing the adhesive to 2-3 times the recommended dose is usually ok.

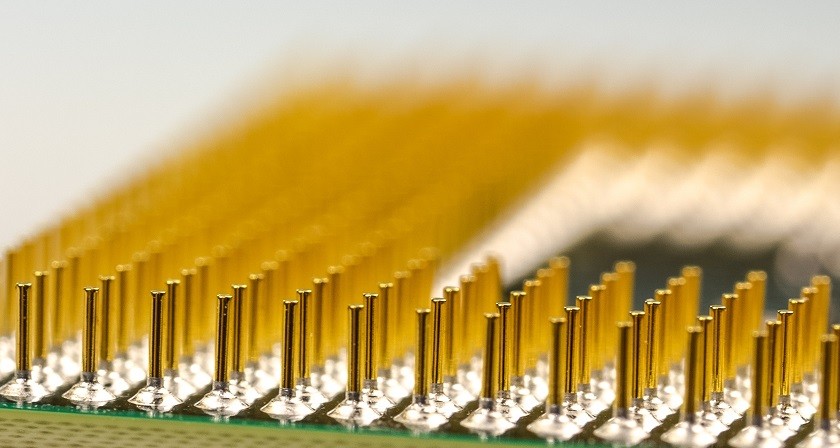

Light curing adhesives are first and foremost used when a fast cure speed is desired. Often, a full cure is achieved in seconds and that is also the main advantage of this type of adhesive.

There are certain requirements that must be fulfilled to be able to use light curing adhesives for an application.

Probably, two materials (‘substrates’) are being bonded together. This means that at least one of these materials must transmit the light so that it can reach the bond line. All materials do not have 100 % transmission of UV/Vis light and a transparent material is required. In addition, some plastics, for example, can be UV blocking, even though they are transparent. In some cases, the plastic can be cured with blue light (405 nm).

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Read more