Moisture curing silicone adhesives and sealants

Learn more about how 1-component moisture curing silicone adhesives work, what to consider, when it is suitable to use one and advantages.

Learn more about how 1-component moisture curing silicone adhesives work, what to consider, when it is suitable to use one and advantages.

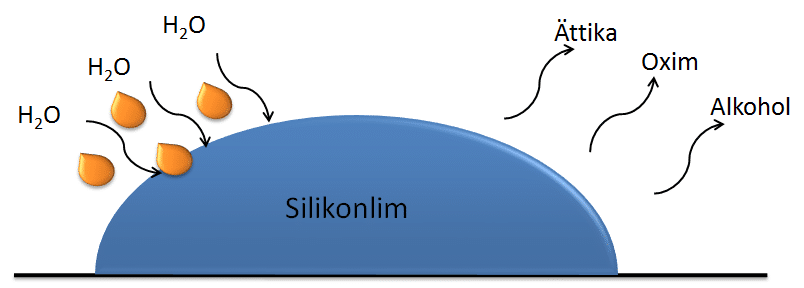

A 1-component RTV silicone is cured with moisture unlike a 2-component silicone adhesive which cures upon mixing. The moisture curing silicone will cure from the outside in which means that first, a skin will be formed on the surface. This is a relatively fast process, perhaps 10 minutes at normal temperature and humidity. What it means in reality is that this is the time you have after dispensing until your pieces should be bonded (otherwise known as the ”open time”, ”tack free time” or ”skin formation time”). After the skin has formed, the adhesive will continue to cure inwards which takes longer. A normal cure speed is approximately 2 mm/24 hours, counted from the surface of the adhesive that is in contact with air.

The great advantage of choosing a 1-component silicone adhesiva as compared to a 2-component one is not the cure speed, but the ease of dispensing.

Chemically, what happens during curing is that tiny water molecules creep into the silicone. There they chemically react with the components of the silicone adhesive and create a by-product. Depending on the type of adhesive, this by-product can be either an alcohol (alkoxy), acetic (acetoxy), an oxime or more uncommonly, an amine.

The curing speed of 1-component moisture curing silicones is directly dependent on the:

The influence of relative humidity should be clear by now – it is the water molecules in the air that are needed to kick off the chemical curing reaction at all. A higher temperature make the molecules in the adhesive more mobile which allows them to react more quickly. However, be careful not to increase the temperature too much (above approximately 60 ˚C). A too high temperature can degrade the components and either prevent cure altogether or impair the end physical properties.

Bonding, sealing and fixating.

1-component moisture curing silicone adhesives have many areas of use in a number of industries: anything from consumer products such as the doors of ovens to applications within aerospace, aviation, denfense, electronics, medical and everything in between.

Do not use a 1-component moisture curing silicone adhesive if you plan on using it in deep sections. The depth is measured from the side of the silicone that is in contact with surrounding air. This means that moisture curing silicones are not suitable for closed-in areas either. In these cases, you will be better off with a 2-component silicone.

Contact us if you are interested in what moisture curing silicones we can offer for your application.

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Read more